Core logic: The critical value balances total repair cost (A) and total replacement cost (B). Choose repair if A ≤ B, and replacement if A > B. Note that total cost includes not only direct expenses (parts, labor) but also easily overlooked downtime losses and subsequent hidden danger costs (from potential re-malfunctions).

I. Key Costs for Critical Value Calculation

Total cost for both repair and replacement has three core components; omitting any leads to wrong decisions:

1. Direct Cost: Repair cost = labor + consumables; Replacement cost = new part (procurement/transport) + installation.

2. Downtime Cost: Loss from inactivity, calculated as daily construction income × downtime days. Critical for tight schedules as it often exceeds direct costs.

3. Subsequent Hidden Danger Cost: Arises from shorter lifespan of repaired parts (risk of re-malfunction). Formula: (Remaining life of repaired part ÷ Life of new part) × Total cost of re-malfunction. Negligible for new parts with warranties.

II. Critical Value Formula & Practical Steps

Calculation is straightforward with clear steps:

1. Core Formula: A (Total repair cost) = Repair fee + Repair downtime cost + Subsequent hidden danger cost; B (Total replacement cost) = New part cost + Installation fee + Replacement downtime cost; Critical value = A – B. Choose repair if ≤0, replacement if >0.

2. Steps: ① Collect data (malfunction type, costs, downtime, daily income, lifespan); ② Calculate A and B (ignore new parts’ hidden danger cost); ③ Compare A and B to decide.

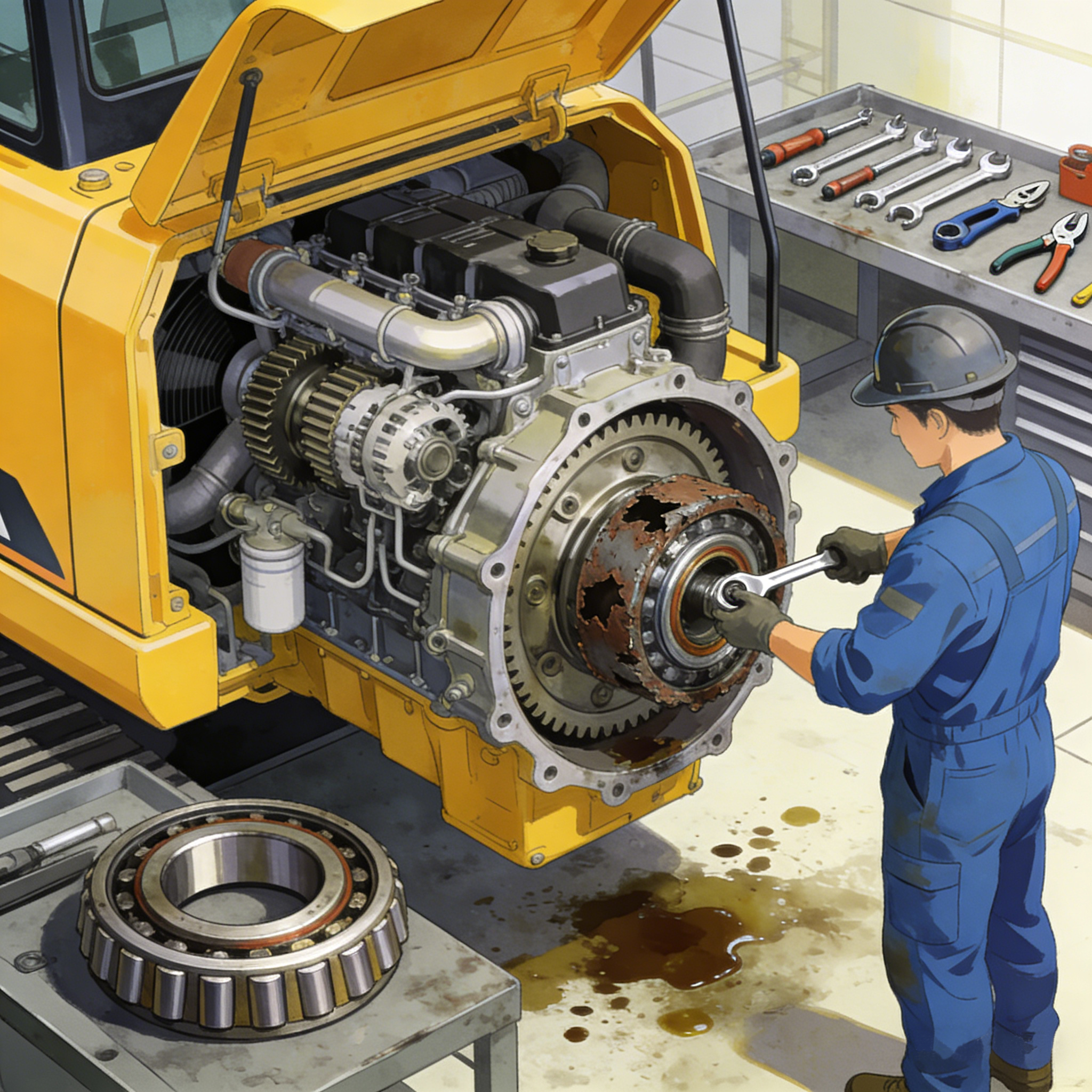

III. Simplified Cases for Common Parts

Key takeaways from 3 typical cases:

1. Bucket Teeth (Wear Part): Severely worn teeth = replace directly. Slightly worn tooth seats: Repair cost (≈USD$260) > Replacement cost (≈USD$240) → Choose replacement.

2. Hydraulic Pump (Core Part): Repair cost (≈USD$1750) > Replacement cost (≈USD$1400) → Choose replacement to avoid secondary downtime.

3. Track Link (Transmission Part): Repair cost (≈USD$830) < Replacement cost (≈USD$1100) → Choose repair for cost savings.

IV. Critical Value Reference for Different Parts

General standards for quick daily judgment:

1. Wear Parts (Bucket Teeth, Filters): Critical value ≤20% of new part cost. Filters = replace directly.

2. Core Components (Hydraulic Pump, Engine Parts): Critical value ≤50% of new part cost. High re-malfunction risk → replace if repair cost exceeds 50%.

3. Transmission/Structural Parts (Tracks, Pins): Critical value ≤60% of new part cost. Prioritize repair if remaining life ≥30% of new parts.

V. Money-Saving Decision Tips

dangers may far exceed the money saved.1. Construction Period Priority: For tight schedules with high daily downtime loss, replace directly even if repair cost is slightly lower.

2. Consider Part Scarcity: If the part is an imported scarce part with a long procurement cycle (e.g., more than 15 days), and repair can restore operation in a short time, even if the repair cost is close to the critical value, you can first repair it for emergency use, and then replace it with a new part later.

Finally, remind everyone: The critical value calculation is not static and should be flexibly adjusted according to your own project conditions, part market prices, and construction rhythm. The core is not to only look at the immediate repair/part costs, but to include downtime losses and subsequent hidden danger costs in the calculation to make the most cost-effective decision.