SANY excavators are renowned for their robustness and efficiency in construction, mining, and infrastructure projects. However, the performance and lifespan of these machines heavily depend on the quality of replacement parts used. Choosing the right SANY excavator parts requires a systematic approach that combines compatibility verification, authenticity identification, and reliable supplier selection. This guide outlines key steps and practical tips to help you make informed purchasing decisions.

1. Prioritize Compatibility: Match Parts to Your Excavator Model

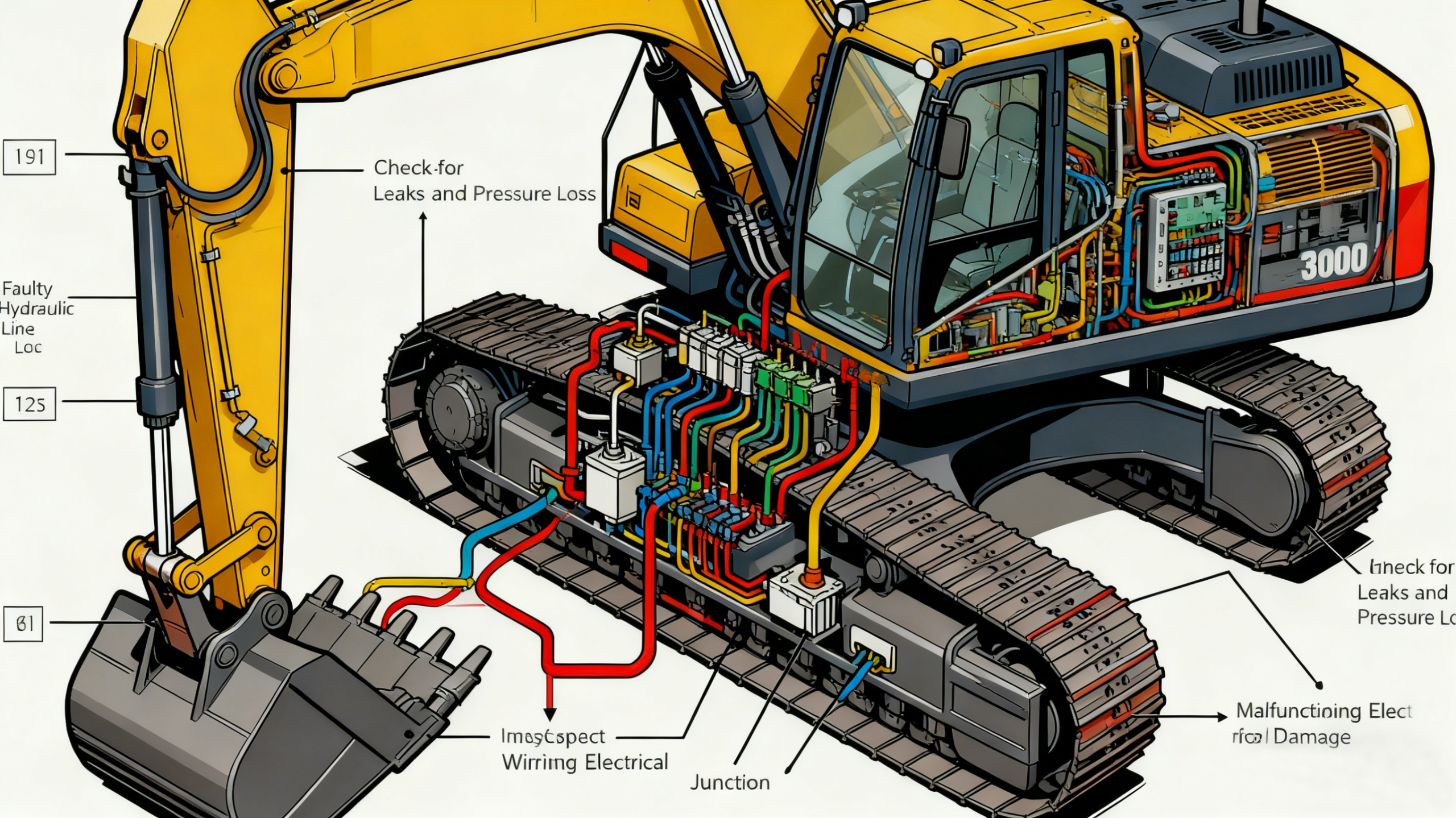

The first and most critical step in purchasing Sany excavator parts is ensuring perfect compatibility with your specific machine model. Incompatible parts not only fail to function properly but may also cause irreversible damage to the excavator’s engine, hydraulic system, or chassis.

- Confirm Core Information: Clearly note your excavator’s model (e.g., SY215C, SY335C, SY365H), production year, and serial number. These details are usually found on the machine’s nameplate or in the operation manual. For key components like hydraulic cylinders, pumps, or filters, reference the original part number (e.g., 60164190 for Sany swing motor) to avoid confusion.

- Match Technical Specifications: Pay attention to technical parameters such as dimensions, material grade, and performance indicators. For example, bucket teeth for rock-breaking applications require higher alloy steel content than those for general-purpose digging. When purchasing hydraulic seals, ensure the pressure resistance and temperature range match the excavator’s working conditions.

2. Methods for distinguishing different qualities

2.1 Observe Component Details

- Filters (Air, Fuel, Oil): Genuine air filters feature evenly spaced wire meshes coated with white paint on the outside and uniform welding on the inside. Their filter paper is dense, thick, and fixed with metal clips. Counterfeits have uneven mesh spacing, rough welding, and use staples or threads to fasten low-quality filter paper. Genuine fuel and oil filters have bright paint, uniform bottom drilling, and smooth threads, while fakes appear dull with asymmetrical drilling and burrs on threads.

- Bucket Teeth: Authentic Sany bucket teeth have clear cast logos and part numbers, thick sidewalls, and tight fitting between the seat groove and tooth root. Each genuine tooth adheres to a fixed weight standard. Counterfeits lack clear logos, have thin walls, and poor fitting, leading to easy loosening during operation.

- Seals and O-rings: Genuine oil seals have smooth skeletons without residual rubber, while counterfeits often have excess rubber residues. Original hydraulic seals are pre-lubricated at the installation port to ensure sealing performance, a feature rarely seen in fakes.

2.2 Check Packaging

Genuine Sany parts come in neat, well-printed packaging with clear labels including part numbers, production dates, and quality certifications. Imported parts have accurately translated labels with no color distortion. Counterfeit packaging is rough, with blurry printing and inconsistent colors.

2.3 Verify Anti-Counterfeiting Marks

Many new Sany parts are equipped with unique anti-counterfeiting codes or QR codes. You can verify authenticity by scanning the code through Sany’s official app or website.

3. Select Reliable Suppliers: Ensure Purchase Security

Choosing a trustworthy supplier is as important as identifying genuine parts. It guarantees product quality, provides after-sales support, and avoids purchase risks.

3.1 Prioritize Official Channels

The most reliable sources for genuine parts are Sany’s official website and authorized dealers. The official website offers one-stop purchasing services, with detailed product introductions, compatibility information, and online payment options. Authorized offline stores provide on-site inspection opportunities, and professional sales staff can offer personalized recommendations based on your needs. Both channels ensure 100% authentic products and formal after-sales guarantees.

3.2 Evaluate Third-Party Suppliers

If choosing third-party suppliers, conduct strict qualification reviews:

Check for production certifications (e.g., special equipment manufacturing license) and quality management system certifications like ISO 9001.Assess industry reputation through third-party platform reviews and peer recommendations.Request technical documents for core processes (e.g., heat treatment, precision machining) to ensure manufacturing standards meet Sany’s requirements.

3.3 Focus on After-Sales Service

Qualified suppliers provide complete after-sales services, including return and exchange policies for defective parts, installation guidance, and maintenance support. Avoid suppliers that refuse to provide after-sales commitments or have vague warranty terms.

4. Additional Purchasing Tips

- Maintain Purchase Records: Keep invoices, delivery notes, and warranty certificates for each purchase. These documents are essential for after-sales claims and traceability.

- Batch Testing for Bulk Purchases: When buying large quantities of parts (e.g., filters, seals), test a small batch first to verify quality and compatibility before full procurement.

- Consult Experienced Personnel: Bring experienced maintenance personnel or machine operators when purchasing complex parts. Their on-site judgment can help avoid misselection.